Amaphaneli e-composite e-laminate (HPL) anamandla aphezulu athandwa kakhulu ezimbonini ezahlukahlukene ngenxa yokusebenza kwawo okuphezulu kanye nezinhlelo zokusebenza eziguquguqukayo. Amaphaneli enziwe ngokuhlanganiswa kwezinto ze-HPL kanye ne-honeycomb core, okudala isakhiwo esilula kodwa esiqinile. Ukuqonda izakhiwo ezibalulekile, izinzuzo kanye nokubi kwamaphaneli e-composite e-HPL kubalulekile ekwenzeni izinqumo ezinolwazi mayelana nokusetshenziswa kwawo ezindaweni ezahlukene.

Izimiso kanye nokusebenza kwamaphaneli e-HPL composite

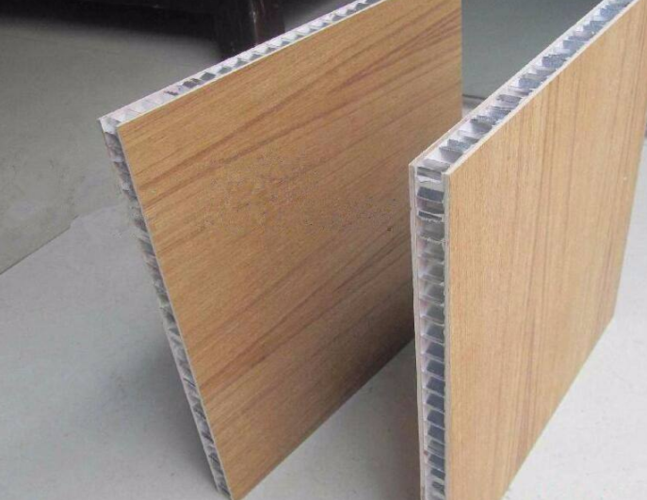

Izakhiwo ezibalulekile zeAmaphaneli e-HPL ahlanganisiweKuncike ekuhlanganisweni kwezinto ezisetshenziswa ekwakhiweni kwazo. Eyaziwa ngokumelana kwayo okukhulu nokuguguleka, umthelela kanye nomswakama, izinto ze-HPL zakha ungqimba lwangaphandle lwamaphaneli. Lokhu kunikeza isivikelo esihle kakhulu ezintweni zangaphandle, okwenza iphaneli ifaneleke kokubili ukusetshenziswa kwangaphakathi nangaphandle. Ama-core e-honeycomb ngokuvamile enziwa ngezinto ze-aluminium noma ze-thermoplastic, okusiza ekwenzeni amaphaneli abe lula ngenkathi egcina ubuqotho besakhiwo.

Izinzuzo zamaphaneli e-HPL ahlanganisiwe

1. Ukuqina: Amaphaneli e-HPL ahlanganisiwe aqinile kakhulu futhi afanelekela izindawo ezinabantu abaningi kanye nezindawo lapho ukumelana nokushayisana kubalulekile khona. Ingqimba yangaphandle ye-HPL inikeza isivikelo esiphezulu ekuklwebhekeni, ekuklwebhekeni nasekuchayweni ngamakhemikhali, okuqinisekisa ukusebenza kwesikhathi eside.

2. Isisindo esincane: I-honeycomb core esetshenziswa kumaphaneli e-HPL inciphisa kakhulu isisindo sawo ngaphandle kokwehlisa amandla. Lokhu kwenza amaphaneli abe lula ukuwaphatha ngesikhathi sokufakwa futhi kunciphisa umthwalo ophelele esakhiweni, okwenza kube kuhle kakhulu ekusetshenzisweni lapho isisindo siyinkinga.

3. Ukumelana nesimo sezulu: Amaphaneli e-HPL ahlanganisiwe abonisa ukumelana nesimo sezulu okuhle kakhulu, okwenza afaneleke ezindongeni zangaphandle, ezimpawini kanye nasefenisha yangaphandle. Izinto ze-HPL ziyakwazi ukumelana nokuchayeka kwe-UV kanye nomswakama, okuqinisekisa ukuthi amaphaneli agcina ubuhle bawo kanye nokuqina kwesakhiwo ngokuhamba kwesikhathi.

4. Ukuguquguquka: Amaphaneli e-HPL ahlanganisiwe atholakala ngemibala ehlukahlukene, ukuthungwa, kanye nokuqedwa, okuvumela izinketho ezahlukene zokuklama. Angasetshenziswa ezinhlotsheni ezahlukene zokuklama izakhiwo nezangaphakathi, kufaka phakathi ukumbozwa kodonga, izingxenye zodonga, ifenisha kanye nezinto zokuhlobisa.

5. Ukulungiswa okuphansi: Ubuso obungenazimbobo bebhodi le-HPL kwenza kube lula ukuhlanza nokunakekela. Azinabala futhi azidingi ukulungiswa okuningi, okwenza kube inketho engabizi kakhulu ngokuhamba kwesikhathi.

Izinkinga zamaphaneli e-HPL ahlanganisiwe

1. Izindleko: Nakuba amaphaneli e-HPL ahlanganisiwe enikeza izinzuzo eziningi, angabiza kakhulu uma kuqhathaniswa nezinye izinketho zokumboza noma zokumboza. Ukutshalwa kwezimali kokuqala okudingekayo kula maphaneli kungavimbela amanye amaphrojekthi asebenzisa isabelomali ekuwasebenziseni.

2. Izakhiwo zokuvikela ukushisa ezilinganiselwe: Amaphaneli e-HPL ahlanganisiwe anezakhiwo zokuvikela ukushisa ezilinganiselwe uma kuqhathaniswa nezinye izinto zokwakha. Lokhu kungathinta ukufaneleka kwawo ekusetshenzisweni lapho ukusebenza kokushisa kuyisici esibalulekile.

Izindawo zokusetshenziswa kanye nezinzuzo zezindleko

Amaphaneli e-HPL ahlanganisiwe asetshenziswa kabanzi ezimbonini ezahlukahlukene kanye nezicelo ngenxa yenhlanganisela yawo eyingqayizivele yezakhiwo. Ezinye izindawo ezibalulekile zokusetshenziswa kanye nezinzuzo zezindleko zifaka:

1. Ukufakwa Kwesivikelo Sesakhiwo:Amaphaneli e-HPL ahlanganisiweZivame ukusetshenziselwa ukumbozwa kwangaphandle kwezakhiwo zezentengiselwano nezindawo zokuhlala. Ukuqina kwazo, ukumelana nesimo sezulu, kanye nobuhle kuzenza zibe ukukhetha okuthandwayo kokuthuthukisa ukubukeka nokuvikelwa kwesakhiwo.

2. Umklamo Wangaphakathi: Ukuguquguquka kwamaphaneli e-HPL kuvumela ukuthi asetshenziswe ezinhlelweni zokuklama ngaphakathi njengamaphaneli odonga, izingxenye kanye nefenisha. Uhla lwayo olubanzi lokuqedwa kanye nokuthungwa kunikeza abaklami ukuguquguquka kokudala izikhala ezikhangayo nezisebenzayo.

3. Ezokuthutha: Amaphaneli e-HPL ahlanganisiwe asetshenziswa embonini yezokuthutha ukuze kusetshenziswe njengezangaphakathi zezimoto, izingxenye zasolwandle, kanye nezakhiwo zezindiza. Ukukhanya kwawo nokuqina kwawo kuwenza afanelekele ukuthuthukisa ukusebenza kanye nobuhle bezimoto zokuthutha.

4. Inzuzo yezindleko: Nakuba izindleko zokuqala zamaphaneli ahlanganisiwe e-HPL zingase zibe phezulu kunezinye izinto zokwakha zendabuko, izinzuzo zayo zezindleko zesikhathi eside azinakwa. Izidingo zokunakekelwa okuphansi kwephaneli, impilo yesevisi ende kanye nokumelana nokuguguleka kunegalelo ekongeni izindleko iyonke phakathi nomjikelezo wayo wokuphila.

Ngamafuphi, amaphaneli e-HPL ahlanganisiwe anikeza inhlanganisela eyingqayizivele yezakhiwo, izinzuzo kanye nokungalungi ngezinto zawo ze-HPL kanye nesakhiwo se-honeycomb core. Ukuqonda lezi zici kubalulekile ekwenzeni izinqumo ezinolwazi mayelana nokusetshenziswa kwawo ezinhlotsheni ezahlukene. Naphezu kwezindleko zawo zokuqala ezilinganiselwe kanye nezakhiwo zokuvikela ukushisa, ukuqina, ukukhanya, ukumelana nesimo sezulu, ukuguquguquka kanye nezinzuzo zezindleko zesikhathi eside kwenza amaphaneli e-HPL ahlanganisiwe abe ukukhetha okuthakazelisayo kwezinhlobo ezahlukene zokwakha, ukuklama kwangaphakathi kanye nezinhlelo zokusebenza zokuhamba. Njengoba ubuchwepheshe nezinto zokwakha ziqhubeka nokuthuthuka, amaphaneli e-HPL ahlanganisiwe angase ahlale eyinketho ebalulekile yezixazululo zokwakha ezintsha nezisimeme.

Isikhathi sokuthunyelwe: Septhemba-03-2024